We are unable to deny the importance of the Pharmaceutical Industry Machine Vision Systems. The Pharmaceutical Industry Machine Vision Systems play a pivotal role in ensuring the quality and efficiency of pharmaceutical manufacturing processes. Within this highly regulated sector, where adherence to FDA regulations is non-negotiable due to the gravity of potential production faults, machine vision emerges as a crucial technology. Beyond mere quality control, machine vision systems contribute significantly to enhancing overall efficiency while maintaining stringent quality standards.

Evolution in Pharmaceutical Machine Vision

The pharmaceutical sector stands out as an early adopter of machine vision technology, primarily due to its enduring commitment to product purity and safety. Over time, this technology has undergone substantial improvements, reaching a point where it now caters to highly specialized pharmaceutical applications, fostering productivity in multifaceted ways. Its integration into the industry has transformed critical processes, reflecting a remarkable evolution in the application of machine vision.

Diverse Applications of Machine Vision

In the pharmaceutical industry, machine vision finds its primary utility in manufacturing, transportation, and data processing. The versatility of machine vision technology becomes evident in its ability to mechanize diverse applications, significantly impacting essential procedures within the pharmaceutical production pipeline. Its adoption spans various facets of the industry, showcasing a broad spectrum of applications that contribute to the overall efficiency and reliability of pharmaceutical processes.

High-Level Overview

This article aims to delve into the significance of machine vision systems specifically tailored for the pharmaceutical business. However, before delving into the intricacies, it is imperative to present a high-level overview, providing a glimpse into the comprehensive role that machine vision plays within the pharmaceutical sector.

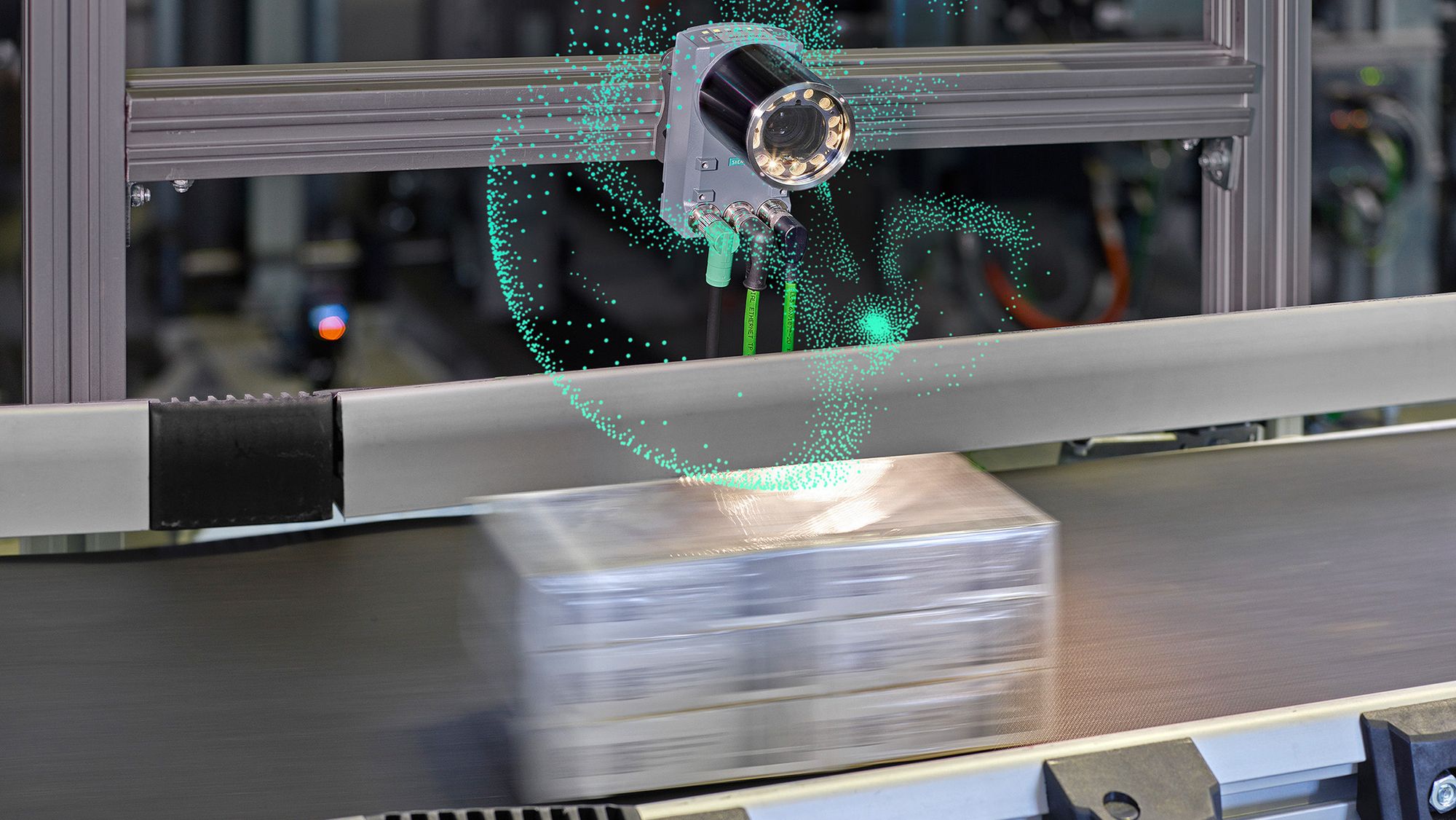

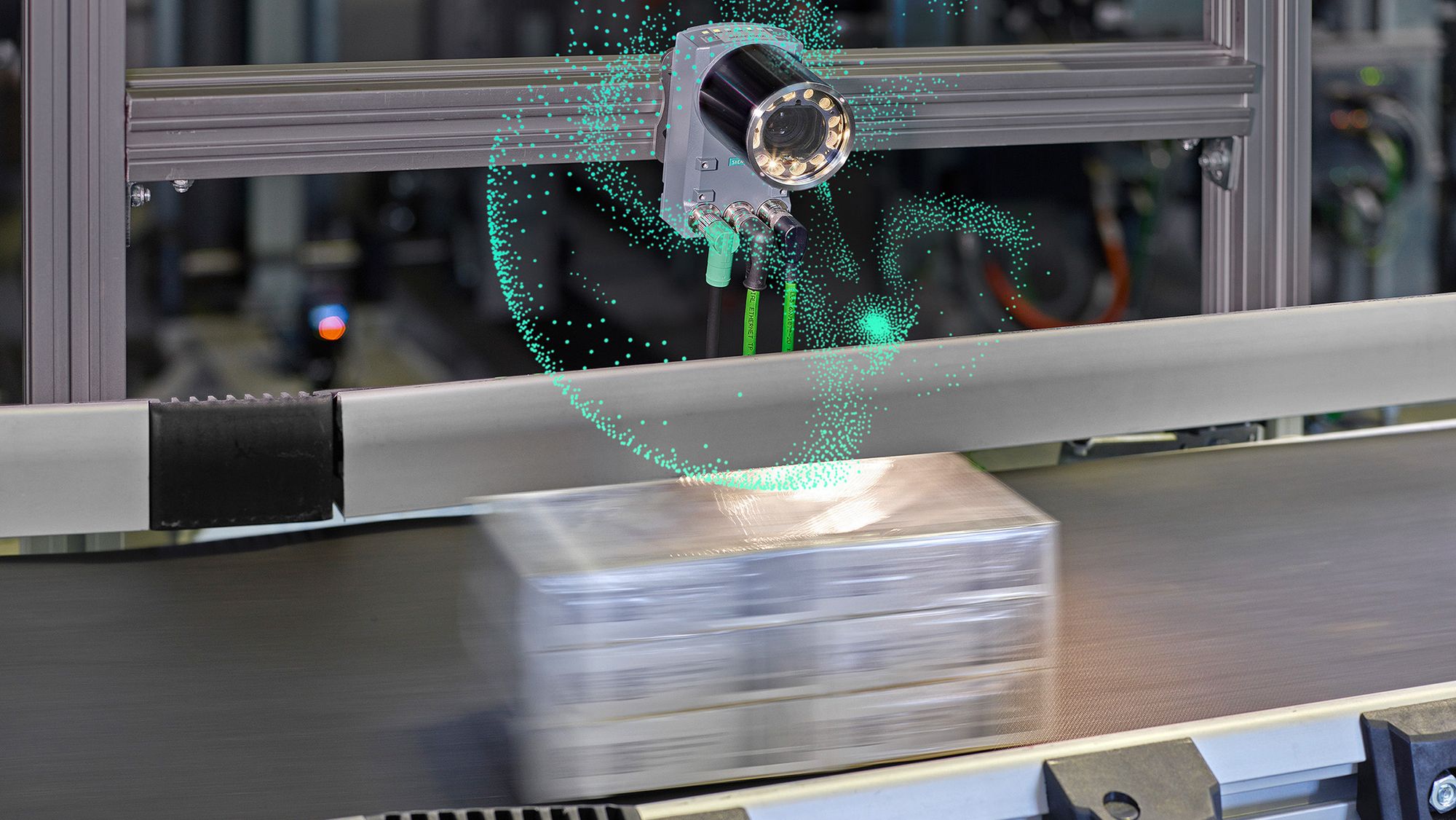

Automated Inspection Processes

Machines, powered by machine vision systems, serve as formidable replacements for or supplements to human labor. Through the integration of cameras, lasers, and sensors, these automated systems meticulously scrutinize incoming parts, ensuring they meet the stringent quality standards set by the FDA. This becomes particularly critical in pharmaceutical manufacturing, where products directly impact human health, necessitating meticulous inspection to identify flaws or any undesired materials.

Stringent FDA Requirements

The pharmaceutical industry faces unique challenges given the FDA’s stringent requirements for inspecting pharmaceuticals before they reach the market. This is not merely a bureaucratic hurdle; rather, it is a vital safeguard to ensure that products destined to safeguard human health adhere to specific quality standards. Machine vision systems play a crucial role in meeting these requirements, effectively identifying issues such as missing components, foreign objects, incorrect labeling, and packaging problems. Through this, machine vision becomes a linchpin in maintaining the integrity and safety of pharmaceutical products.

Advantages of Adopting Machine Vision in the Pharmaceutical Sector

Enhancing Product Quality:

One of the paramount advantages of integrating machine vision systems in the pharmaceutical sector lies in their ability to detect and rectify faults during the manufacturing process. Through real-time monitoring and precise identification of deviations from quality standards, machine vision plays a pivotal role in elevating product quality. This proactive approach not only ensures adherence to stringent regulatory requirements but also minimizes the likelihood of defective products reaching the market, bolstering the reputation of pharmaceutical companies.

Facilitating Regulatory Compliance:

The pharmaceutical industry operates within a highly regulated environment, with compliance to strict standards, particularly those set by the FDA, being non-negotiable. Machine vision systems act as indispensable tools in achieving and maintaining regulatory compliance. By providing a meticulous and automated inspection process, these systems ensure that every pharmaceutical product meets the prescribed quality benchmarks. This not only safeguards public health but also shields pharmaceutical companies from regulatory penalties and reputational damage.

Boosting Production Productivity and Efficiency:

Machine vision systems are catalysts for increased production productivity and operational efficiency within the pharmaceutical sector. Through the automation of inspection processes, these systems streamline manufacturing operations, reducing the need for manual intervention and minimizing the time required for quality checks. This boost in efficiency translates into higher production rates, allowing pharmaceutical companies to meet market demands more effectively while maintaining consistent product quality.

Minimizing Product Rejections and Waste

A significant financial and operational advantage of machine vision adoption is the reduction of product rejections and waste in pharmaceutical manufacturing. By identifying and addressing faults in real time, these systems minimize the production of defective or substandard products. This not only saves on raw materials but also reduces the overall environmental impact by curbing unnecessary waste. The economic and ecological benefits of waste reduction contribute to the sustainability and profitability of pharmaceutical operations.

Providing Comprehensive Inspection Data:

Machine vision systems go beyond mere defect detection; they provide comprehensive inspection data that can be leveraged to enhance manufacturing processes. The detailed insights generated by these systems offer a valuable resource for continuous improvement. Pharmaceutical companies can analyze this data to identify patterns, optimize production workflows, and implement proactive measures to prevent issues before they occur. This data-driven approach aligns with the industry’s pursuit of excellence and continuous enhancement of manufacturing practices.

Quality Assurance in the Pharmaceutical Sector

In the intricate landscape of the pharmaceutical sector, machine vision systems emerge as indispensable tools in the realm of quality assurance. Beyond mere technological contrivances, they assume a pivotal role in the meticulous scrutiny of every facet of pharmaceutical production, poised as vigilant sentinels against the specter of substandard products infiltrating the market. These systems, with their discerning lenses and sensors, play a paramount role in the unyielding pursuit of regulatory compliance, acting as custodians of pharmaceutical integrity.

This technological tapestry unfolds its significance by meticulously sifting through the incoming components, subjecting them to rigorous scrutiny facilitated by cameras, lasers, and sensors. In the pharmaceutical labyrinth, where precision is not a luxury but a necessity, this proactive quality control mechanism becomes the vanguard of product safety. Each nuance, each molecular irregularity, is subjected to the relentless gaze of machine vision systems, ensuring that the end customer receives not just a product, but an epitome of pharmaceutical excellence.

The Crucial Nexus of Quality Control and FDA Compliance

Within the pharmaceutical echelons, the symbiosis between machine vision systems and quality control establishes an intricate dance. It is not merely about identifying flaws or undesirable materials; it transcends into a dance with the stringent cadence of FDA compliance. The lenses and sensors, akin to meticulous choreographers, orchestrate a ballet where regulatory criteria become the choreography, and product safety of the grand performance.

Quality control, a veritable bedrock of the pharmaceutical citadel, finds its bastion in the discerning eyes of machine vision systems. A microscopic misstep in the manufacturing process can have repercussions that reverberate far beyond the confines of the production floor. The ability to detect missing components, foreign objects, inaccurate labeling, or packaging anomalies becomes the pantheon upon which the temple of pharmaceutical integrity rests. The comprehensive inspection data these systems provide serve not just as a record but as a tool, a repository of insights that illuminate the path toward continuous process improvement.

The Symphony of Efficiency Through Quality Control

The crescendo of machine vision systems reverberates not only in the domain of quality assurance but also in the symphony of efficiency and productivity. As the custodians of industrial throughput, these systems become architects of a streamlined production process, sculpting efficiency from the raw materials to the finished product with the best technologies around the world. In the labyrinth of pharmaceutical intricacies, the reduction of product rejections and waste is not merely a financial triumph; it’s a testament to the virtuosity of machine vision systems.

The orchestra of efficiency and quality assurance, conducted by the vigilant eyes of machine vision, weaves a narrative of heightened productivity. In the dance of precision and speed, these systems transcend the conventional boundaries of technological oversight, ensuring that the pharmaceutical industry doesn’t just meet but exceeds the expectations of both regulatory bodies and end consumers.

Final Product Inspection: A Culmination of Assurance

The denouement of this technological saga is the final product inspection, a crescendo that echoes the weight of consumer expectations and regulatory scrutiny. It is here, on the precipice of market release, that machine vision systems unfold their final act. Like meticulous curators, they examine each finished product with an intensity that mirrors the significance of what is at stake—consumer safety, regulatory compliance, and the sanctity of the company’s reputation.

The final product inspection, a ritualistic passage through the meticulous gaze of cameras, lasers, and sensors, becomes a pilgrimage of assurance. Beyond the binary realms of acceptance or rejection, it is a nuanced exploration of the shades of quality, ensuring that each item not only meets but surpasses the specified criteria. This ritual is not merely a safeguard against recalls; it is a pledge, a covenant with consumers that echoes in the echelons of brand loyalty.

Imperfections in the Perfection: The Limitations of Machine Vision Systems

Yet, amidst the grandeur of technological prowess, it is paramount to acknowledge the imperfections in the perfection of machine vision systems. In the grand tapestry of quality control, where the stakes are high and precision non-negotiable, these systems, for all their sophistication, are not infallible. The areas where several goods are assessed simultaneously become the crucible of challenge, a frontier where the limitations of machine vision systems are laid bare.

In the landscape of quality control, acknowledging the inherent fallibility of machine vision systems becomes the catalyst for continuous improvement. While they stand as stalwart guardians in the pharmaceutical coliseum, there exists a hinterland where human oversight and adaptability become the essential companion pieces of activities such as a pet’s socialization process. The dance between machine precision and human intuition is the equilibrium upon which the future of quality control hinges, a harmonious coexistence where technology augments human capability, but never fully supplants it.

Advantages of Machine Vision Over Human Inspection

The utilization of machine vision systems in product inspection marks a paradigm shift from traditional human-dependent approaches. The inherent accuracy of machine vision surpasses that of human inspectors, significantly mitigating the risks associated with subjective errors that may arise when relying on visual assessments conducted by individuals. The meticulous nature of machine vision allows it to meticulously scrutinize components or goods, unearthing minute flaws or inconsistencies that might elude the human eye.

In addition to heightened accuracy, the efficiency of machine vision inspection is a formidable advantage. The pace at which a machine processes visual data far exceeds the capabilities of a human inspector. This accelerated evaluation translates to a substantial increase in the number of products inspected within a given timeframe. Consequently, this surge in efficiency serves as a catalyst for heightened production efficiency and overall productivity, reshaping the landscape of manufacturing operations.

Moreover, the cost-effectiveness of machine vision inspection emerges as a pivotal factor in its favor. The expenses associated with employing human resources for quality control are notably higher than investing in machine vision systems. This economic efficiency becomes particularly pronounced in industries where precision and consistency are paramount, such as pharmaceuticals. Notably, within the pharmaceutical sector, machine vision systems have ingrained themselves as indispensable tools for ensuring product safety and adhering to the stringent regulations set forth by the FDA.

The Swift Precision of Machine Vision Inspection

A distinctive trait that sets machine vision inspection apart lies in its unparalleled speed and precision. Machines possess the capability to scrutinize, analyze, and evaluate items with a rapidity that transcends human capabilities. This swift precision not only expedites the inspection process but also opens avenues for inspecting a significantly larger volume of products in comparison to manual inspections.

The expeditious nature of machine vision inspections becomes a linchpin in the optimization of manufacturing processes. The accelerated pace ensures that potential faults or deviations from quality standards are swiftly identified and rectified. Consequently, this swift precision becomes an integral component in maintaining the highest levels of product quality and consistency.

Economic Efficiency in the Pharmaceutical Sector

In the intricate landscape of pharmaceutical manufacturing, machine vision systems emerge as catalysts for economic efficiency and regulatory adherence. The stringent quality control measures mandated by the FDA demand a level of precision and consistency that machine vision seamlessly provides. The financial implications of utilizing machine vision systems in the pharmaceutical sector are multifaceted, encompassing not only the reduction in human error-related expenses but also the avoidance of potential regulatory fines resulting from lapses in compliance.

Economic efficiency extends beyond the direct financial aspects, permeating into the broader realm of production efficiency. Machine vision systems, through their rapid and accurate inspections, contribute to the streamlining of manufacturing processes, fostering increased throughput and efficiency. In this intricate dance between precision and speed, machine vision systems prove to be indispensable instruments in the pharmaceutical industry’s pursuit of quality control and regulatory compliance. Health books, guides, exercises, habits, Diets, and more

Conclusion: Machine Vision in Pharmaceuticals

In the intricate tapestry of pharmaceutical manufacturing, machine vision systems emerge as beacons of precision, efficiency, and compliance. They weave seamlessly into the quality control framework, ensuring that every product aligns with the stringent standards set forth by regulatory bodies. From the swift identification of flaws to the expeditious evaluation of a multitude of products, machine vision transforms the landscape of inspection processes.

As a tool for detecting and correcting faults in the manufacturing process, machine vision systems play a pivotal role in the pharmaceutical industry. Their multifaceted contributions encompass not only the enhancement of production efficiency and throughput but also the meticulous scrutiny required for final product inspections. In essence, machine vision in the pharmaceutical sector transcends mere technological adoption; it becomes an indispensable instrument, a vigilant guardian of quality, and a key player in the perpetual quest for regulatory compliance.